Portworld ODM Product Development & Manufacturing Process Guide

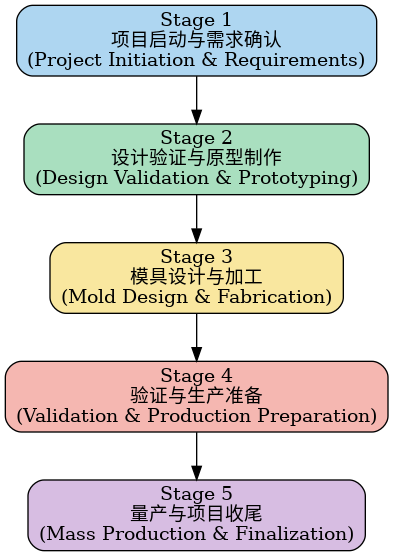

Portworld ODM Project Workflow (Integrated Version)

Stage 1: Project Initiation & Requirements

- Define product positioning and core features

- Complete initial Industrial Design (ID Design) concepts

- Specify hardware and software requirements

- Identify certification and regulatory compliance needs

- Sign NDA agreements

Stage 2: Design Validation & Prototyping

- Create and test the final 3D-printed prototype

- Confirm prototype approval to initiate mold tooling

- Complete concept design planning and prepare for Engineering Validation Test (EVT pre-stage)

Stage 3: Mold Design & Fabrication

- Design and manufacture molds (including CNC dies, soft/hard tooling)

- Produce and test tooling samples

- Finalize mold acceptance and optimization

Stage 4: Validation & Production Preparation

- Conduct EVT, DVT, and PVT testing to validate engineering, design, and production feasibility

- Collaborate on PCBA development and software integration

- Complete required certifications

- Perform PVT tests to ensure production consistency

Stage 5: Mass Production & Finalization

- Begin full-scale mass production

- Execute packaging design and packaging requirement implementation

- Conduct quality checks and manage shipment

- Prepare for End-of-Life (EOL) product lifecycle management