Embedded Linux SBC Boards for Industrial Applications

In the era of Industry 4.0, the demand for intelligent, flexible, and reliable embedded solutions is higher than ever. Among these, Embedded Linux Single Board Computers (SBCs) stand out as a powerful platform for industrial applications, offering high flexibility, robust performance, and strong ecosystem support.

This article explores the key advantages of Linux-based SBCs, common industrial use cases, selection criteria, and why Portworld is a trusted provider of industrial-grade SBC solutions.

What Is an Embedded Linux SBC?

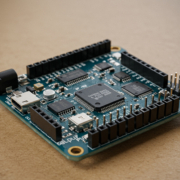

A Single Board Computer (SBC) integrates the processor, memory, storage, and I/O interfaces into a single compact board. Compared to traditional industrial PCs, SBCs are smaller, more power-efficient, and easier to deploy.

When running Linux (such as Ubuntu, Debian, or Yocto), these SBCs become powerful and customizable platforms, ideal for edge computing, industrial automation, AI processing, and intelligent device control.

Why Use Linux SBCs in Industrial Applications?

1. High Reliability and Stability

Industrial environments are often harsh, with wide temperature ranges, dust, and electrical interference. Industrial Linux SBCs are built with rugged components, capable of operating in -20°C to +70°C or wider, and designed for 24/7 stability.

2. Rich Interfaces and Expandability

Most SBCs come with industrial-grade interfaces such as GPIO, RS232/RS485, CAN, Ethernet, HDMI, USB, and MIPI. They also support extension via Mini-PCIe, M.2, SPI, and I2C, making it easy to integrate sensors, displays, and wireless modules.

3. Open-Source and Developer-Friendly

Linux offers a fully open-source environment. Developers can customize the kernel, drivers, and applications, enabling tailored system-level solutions for HMI, real-time control, or remote monitoring.

4. Edge Intelligence and Cloud Connectivity

Modern Linux SBCs support Docker, container deployment, and OTA (Over-the-Air) updates. They can connect with industrial cloud platforms, enabling real-time data analytics and intelligent edge decision-making.

Industrial Application Scenarios for Linux SBCs

| Industry Use Case | Typical Applications |

|---|---|

| Smart Factory | PLC data collection, robotic arm control, HMI displays |

| Intelligent Logistics | AGV systems, barcode scanning, path optimization |

| Smart Retail | Self-service kiosks, digital signage, facial recognition |

| Smart City | Street light control, air quality monitoring, traffic AI |

| Edge AI Processing | Image recognition, voice analysis, anomaly detection |

| Industrial Gateways | Protocol conversion, Modbus/OPC communication, remote I/O |

How to Choose an Industrial-Grade Linux SBC

When selecting an SBC for industrial use, consider the following criteria:

- Processor Performance: Choose ARM Cortex-A series or x86 based on task complexity

- OS Compatibility: Ensure support for Ubuntu, Debian, or Yocto Linux

- Temperature Range: Look for wide-temp models (e.g., -20°C to +70°C)

- I/O Interfaces: Verify support for your specific device or machine interfaces

- Longevity & Support: Ensure long-term availability (3+ years) for project continuity

- Security Features: Look for secure boot, data encryption, and remote OTA updates

Portworld’s Embedded Linux SBC Solutions

As a professional embedded solutions provider, Portworld offers a range of industrial-grade Linux SBCs designed for reliability, flexibility, and performance.

Key Features of Portworld SBCs:

- Quad-core or octa-core ARM Cortex-A processors for balanced power and efficiency

- Support for Ubuntu / Debian / Yocto Linux with SDK and documentation

- Industrial I/O: RS485, CAN bus, dual Ethernet, GPIO, MIPI/HDMI/LVDS display support

- Wide-temperature operation: -20°C to +70°C

- Optional PoE support and low-power sleep modes for energy-critical deployments

- Full customization: Board layout, dimensions, I/O options for OEM/ODM partners

- Technical support and long-term lifecycle commitment

Portworld’s Linux SBCs are already deployed in gateways, industrial control panels, vehicle systems, and smart equipment controllers, helping customers build future-proof industrial systems.